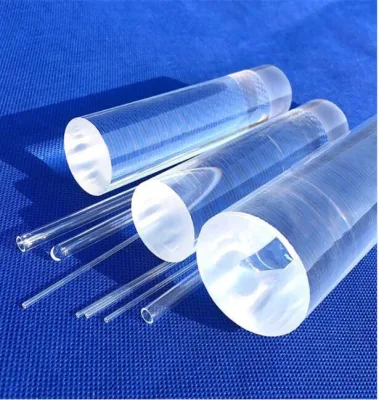

Sight Glass Level Gauge

Overview Product Description Tubular Level Gauges are designed to view liquid levels using clear or red line Borosilicat;

Overview

Features

Three Main technical parameters

Working pressure ≤ 16Kgf/cm3

Working temperature ≤ 200 º C

Needle valve closing pressure: ≥ 2Kgf/cm3

Thermal steam pressure ≤ 6Kgf/cm3

Glass tube size: Φ 19*3mm

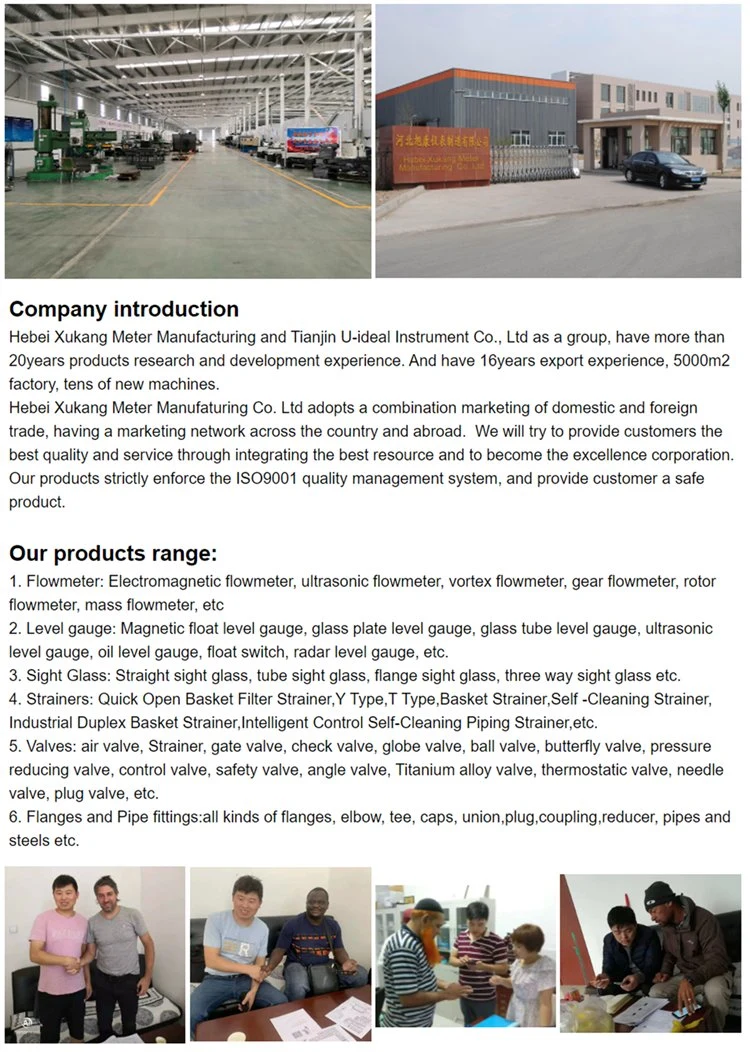

Company Profile

Basic Info.

| Model NO. | GZS-C |

| Warranty | 1 Year |

| Material | SS304 |

| Process Temperature | -190~425℃ |

| Color | Nature, Bi-Color |

| Lamp Power | 24VDC/36VAC/220VAC |

| Quartz Tube Glass Temperature | -20~450 Degree C |

| Ordinary Tube Temperature | 0~100 Degree C |

| Transport Package | Wooden Case or Carton |

| Trademark | U-ideal |

| Origin | Tianjin, China |

| HS Code | 90261000 |

| Production Capacity | 3000PCS/Month |

Product Description

Product DescriptionTubular Level Gauges are designed to view liquid levels using clear or red line Borosilicate (Pyrex) tubing. All valves use a stuffing box configuration to seal the glass tube, and have a ball check shutoff to prevent loss of vessel contents in case of glass failure. Operating pressure and temperatures are subject to the limitations of the tubular gauge glass and washer composition; consult with Pressure Products for gauge glass ratings.

Tubular level gauge is used for visual liquid level indication and is the most commonly used instrument in the process industry. It is a simple and reliable device for level reading in atmospheric or pressurized tank applications. It is mounted parallel, along the side of the tank, so as to form a closed loop. As the process level fluctuates, the level in the transparent glass tube changes accordingly and gives local level indication. The tubular gauge incorporates correct design, rugged construction, proper manufacturing techniques, skilled workmanship to give dependable performance and long service life. Material integrity is assured through strict compliance of chemical composition analysis in a standard laboratory.Features

- Choice of Tie Rod or C-Frame Construction.

- With or without isolating valve.

- Material integrity assured through strict compliance of chemical composition analysis in a Standard Laboratory.

- H Grade Borosilicate glass tube 16/19/25 mm outer dia with Teflon Packing.

- Glass tube can be removed online i.e. without disconnection from vessel

- Standard Connection: 1/2" / 3/4" / 1" Flange drilled to ASA 150#, others on request

- Alluminium/SS scale with 5 mm resolution as standard and 1 mm on request.

- Drain Plug 1/2" Vent Plug 3/4" and drain/vent valve as optional

- Safety Ball check device(optional).

- Defrost/illuminator available on request.

- Hydro test pressure: 12 KG/cm2, 100 Deg C max working temperature.

- Tie Rod Construction is 'light' and permits 360ºC visibility.

- C-Frame construction is robust and permits observation from Front & Rear.

- Both constructions are available in integral or inline arrangements.

- High quality, H grade borosilicate glass tube in 16/19/25mm outer dia is used.

- Available in single length having c/c distance = 1600 mm. Extended lengths are provided by coupling several tubes or gauge assemblies in series.

Three Main technical parameters

Working pressure ≤ 16Kgf/cm3

Working temperature ≤ 200 º C

Needle valve closing pressure: ≥ 2Kgf/cm3

Thermal steam pressure ≤ 6Kgf/cm3

Glass tube size: Φ 19*3mm

| L=C-C distance | 500 | 600 | 800 | 1000 | 1100 | 1200 | 1400 | 2000 |

| H=visible length | 338 | 438 | 638 | 838 | 938 | 1038 | 1238 | 1838 |

| I=glass tube length | 458 | 558 | 758 | 958 | 1058 | 1158 | 1358 | 1958 |

You may also like

Send inquiry

Send now